Energy study TU Delft helps Coolworld become more sustainable

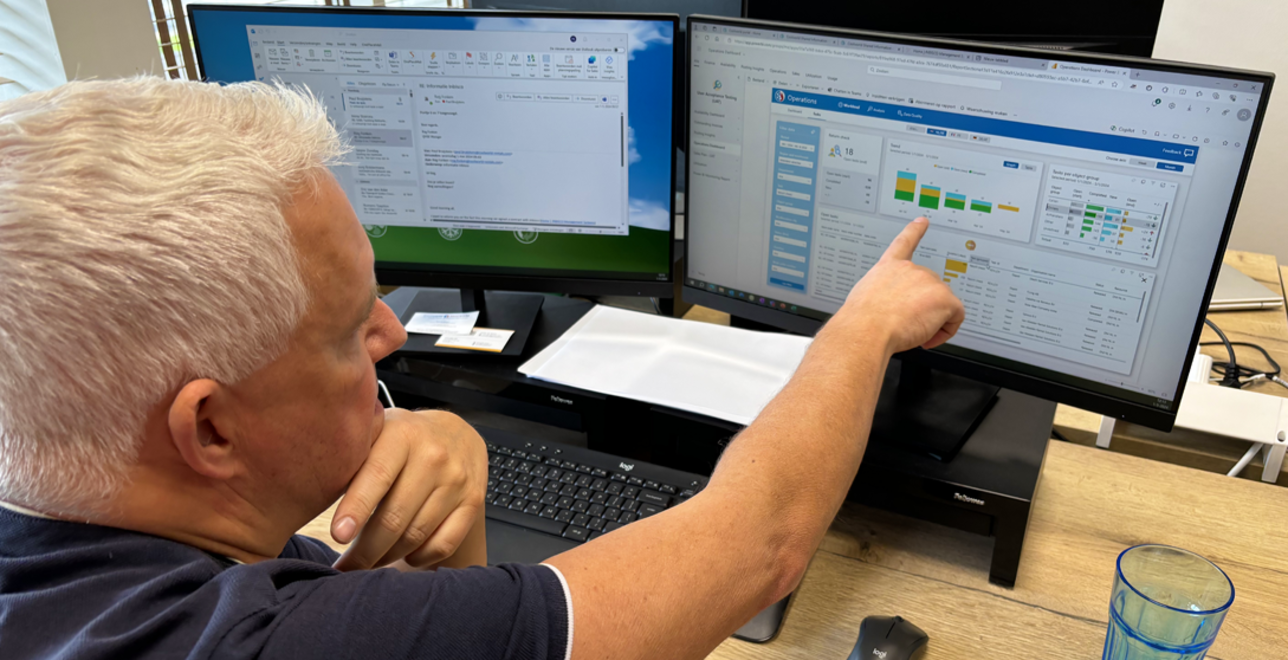

How aware are you of your own energy flows? Where can you optimise energy flows or re-use residual heat? Lars Meeuwisse, master's student in Sustainable Energy Technology at TU Delft went in search of answers. He took a closer look at the test site of Coolworld's headquarters in Waalwijk.

The result of this study:

✔️ Mapping all energy streams

✔️ Improvement opportunities in focus

✔️ New actionable insights. Towards greater sustainability.

Read all about the study and new findings.

It's good to take a fresh look at your processes from time to time. What it yielded? An integral picture of our energy consumption. Insights that make you think again.

4 key outputs of the sustainability study

When you rent a cooling solution from Coolworld, it is first extensively tested. These range from short pre-checks to continuous testing of customised rental installations. For his graduation research, Lars Meeuwisse took a close look at the energy flows at the test site.

More solar power

The testing process creates cold. That residual cold can be used to cool solar panels, making them more efficient and yielding more.

Smart insulation

Part of the test plant is a buffer tank containing 25,000 litres of hot water. By properly insulating this vessel, the water stays at a better temperature.

Smart tests

Pre-testing for a perfectly working cooling solution can be even more efficient. Machine data gives insight into how that test can be shorter and smarter.

Knowledge sharing

We better record knowledge about the testing process and how to use the test rig. We make these more easily accessible to colleagues.

Towards an energy-efficient test process

Global warming, the congested power grid and rising energy prices were three major reasons for scrutinising the test site's energy consumption.

Why the test site? Every year, we perform hundreds of running tests on chillers before they go to customers. In those tests, we often use 20-degree water. This is then cooled down. We then reheat the cooled water for the next test. We were convinced that efficiency gains could be made in the process.

The very thorough investigation into making the test site more sustainable provided new insights and energy-saving improvement possibilities. These measures also contribute to a better environmental climate, making work at the test site more pleasant.

We now have a clear picture of how we can better design the test sites in the Netherlands and in other countries. With this, we are taking important steps towards a more sustainable organisation.

Need temporary installation for your own test setup?

Get a fresh perspective

Lars' graduation research and knowledge from TU Delft, contributed to an integrated picture of our energy flows.

Lars made concrete sustainable improvement proposals. These act as a basis for new improvements as well as insights. Consider:

- making rental installations more efficient,

- the use of data and residual energy flows,

- the starting point for new innovations.

Make time to look at your own processes from a distance. Think and talk about them. Turn them into improvement actions.

We will look for ways to make testing more focused and shorter. For example, by making even smarter use of machine data. The analysis is the basis on which Coolworld can and will build further.

How to receive secure flexible rental solutions? Find out here:

Frequently asked questions

I also want to do my internship at Coolworld. Is that possible?

Yes, you can. Are you looking for a company for an internship? At MBO, HBO or WO level? For 12 weeks or 6 months? On the cutting edge of technology, product development and rental? At Coolworld this is all possible. Read more about our internship opportunities on the working at pages in the netherlands and germany.