Rapid recovery of production process in the high-tech industry thanks to rental of professional chillers

Emergency cooling for cleanrooms and high-tech industry

The complete loss of production due to an external cause - for example failure of the power supply - is enough to put any company under extreme pressure. Production can also be brought to a sudden standstill by a disruption in the company’s own systems. An adequate response from facility management is of vital importance.

Coolworld installs chillers just two hours after the first callout

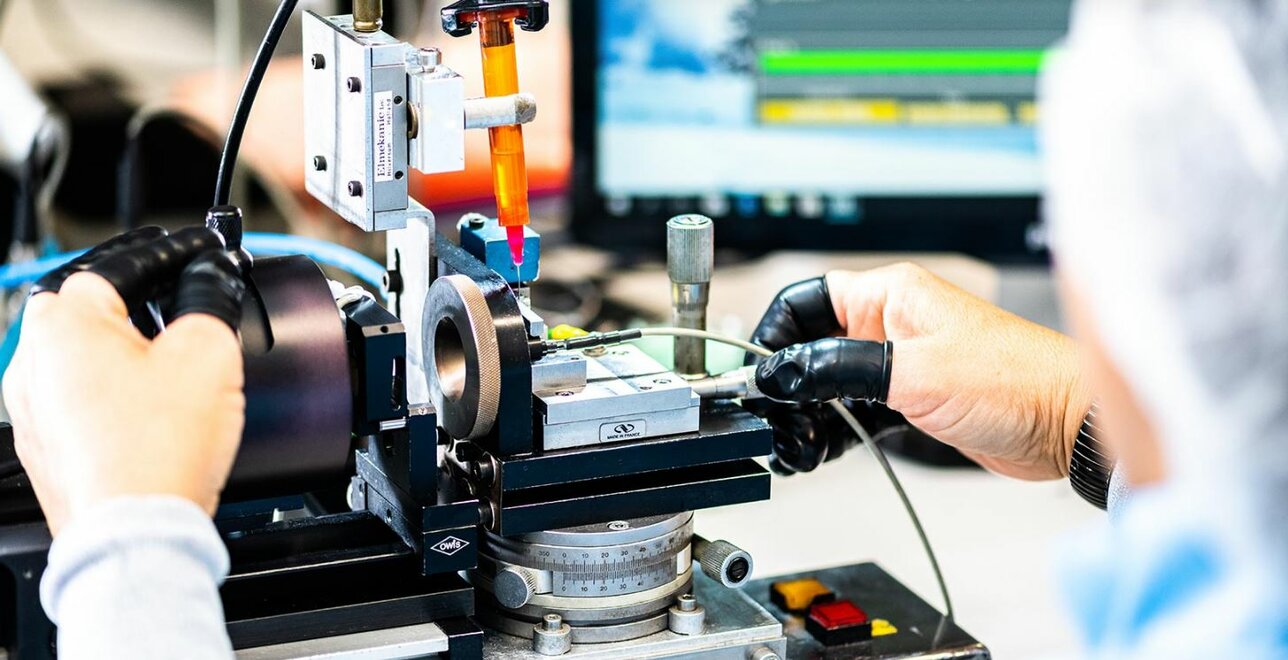

Thanks to its huge rental fleet, even during periods of extreme high temperatures, Coolworld is often able to meet the needs of its clients, from its own depots. Both Anteryon and Coolworld recognise that in an emergency situation, formalities become of secondary importance. Within two hours following the alarm call from Anteryon, the trucks from Coolworld arrived at the Anteryon company location with two heavy-duty chillers, capable of delivering 570 kW of cooling capacity. During the subsequent weekend, Anteryon’s regular installation engineer and technical department joined forces to connect the emergency chiller to the internal cooling system, and to get the system up and running.

“The damage to our business was limited to nothing more than the costs for the rental and installation of the temporary chillers. A fraction of what a long-term production shutdown would have cost,” concluded Anteryon.

Location

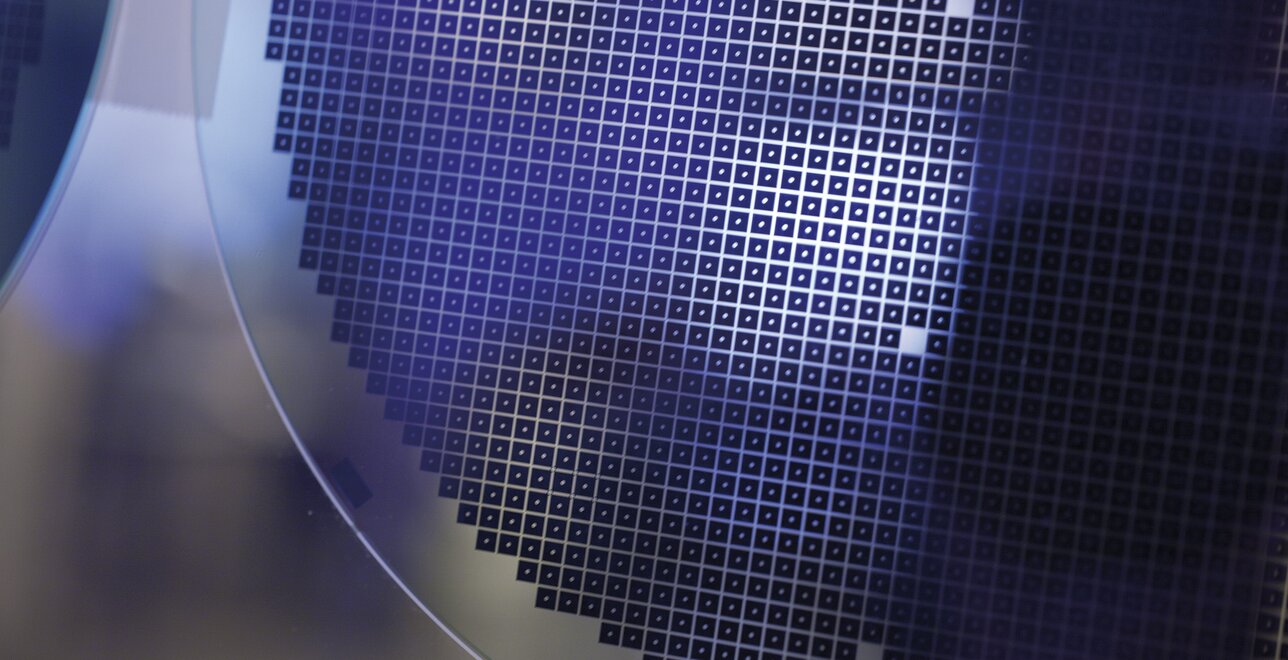

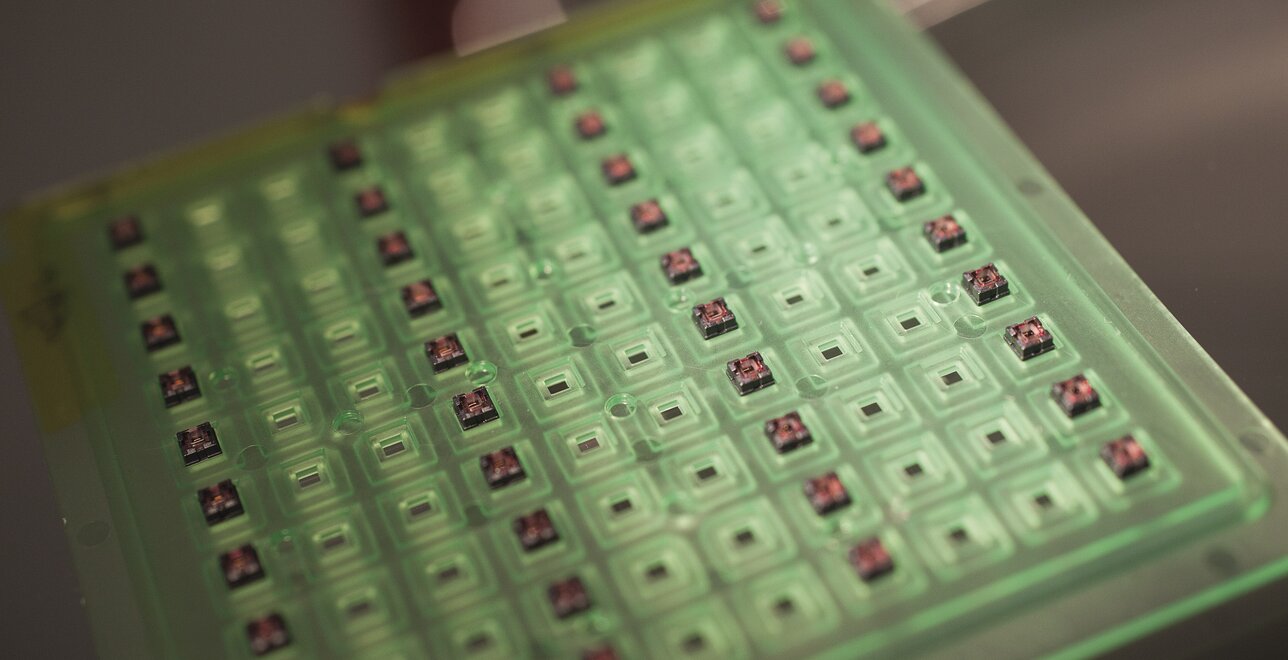

Anteryon, specialists in optomechanical and optoelectronic technologies, the Netherlands.

High-tech industry

Needs & Challenge

Failure of the permanent installation during the summer months. Immediate need for emergency cooling to allow temperature-sensitive production process to continue, undisturbed.

Solution

2 chillers with a combined output of 570 kW.

Advantages

During the hot summer months always (additional) cooling capacity immediately available.

Backup and continuity. Extremely reliable solution, 24/7 service.